LC 2 Wideband Lambda Controller

Introduction

The LC 2 Digital Wideband O₂ Controller is a compact, high accuracy device used to measure lambda (λ) and air fuel ratio (AFR) in both road and motorsport applications. It provides a fast, stable output suitable for data logging, ECU calibration, and engine development work.

The LC 2 is fully compatible with Race Technology data loggers and display systems, allowing lambda or AFR values to be recorded and analysed alongside other engine parameters.

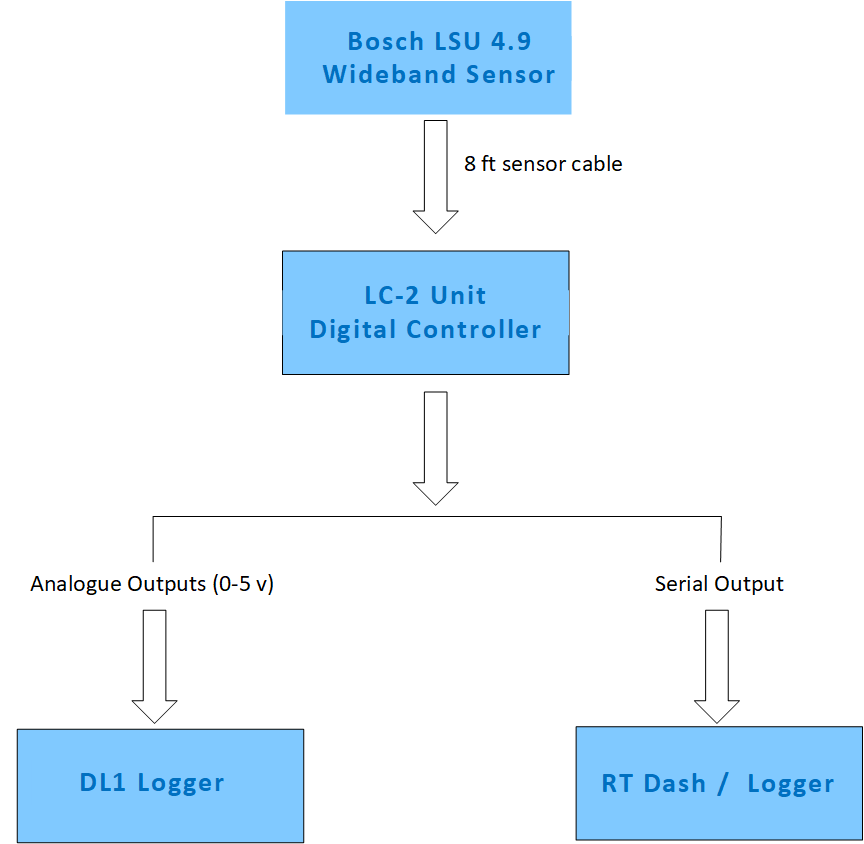

System Overview

System Components

| Component

| Description

|

| LC 2 Controller

| Digital wideband processor module

|

| Bosch LSU 4.9 Sensor

| High accuracy wideband oxygen sensor

|

| 8 ft Sensor Cable

| Connects sensor to controller

|

| Lambda Interface Cable

| Provides analogue + serial outputs

|

| Installation Hardware

| Mounting and wiring accessories

|

System Diagram

Wiring Information (Based on LC 2 Manual)

LC 2 Wiring Colour Table

| Wire Colour

| Function

| Notes

|

| Red

| +12 V Switched Power

| Must be fused; ignition switched

|

| Black

| Ground

| Connect to clean sensor ground

|

| Yellow

| Analogue Output 1

| Default: Lambda/AFR

|

| Brown

| Analogue Output 2

| User configurable

|

| White

| Serial TX

| Digital output

|

| Blue

| Heater Calibration Wire

| Used during initial setup only

|

LED Status Indicators (Summarised from Manual)

LED Behaviour Table

| LED Pattern

| Meaning

|

| Fast blinking

| Sensor heating / warm up

|

| Slow blinking

| Controller active, normal operation

|

| Solid on

| Calibration mode

|

| Rapid irregular blinking

| Sensor or wiring fault detected

|

Heater Calibration (Based on Manual)

The LC 2 requires a one time heater calibration when first installed or when replacing the sensor.

Calibration Summary

- Performed with the sensor in free air

- Blue wire is temporarily grounded to enter calibration mode

- LED will turn solid during calibration

- Calibration completes automatically

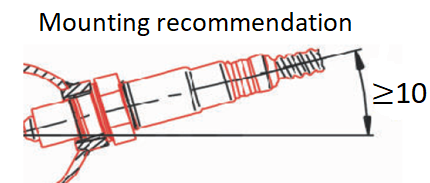

Sensor Installation

Sensor Placement Diagram

Installation Guidelines (Summarised from Manual)

- Install sensor at 10–12 o’clock to prevent condensation damage

- Minimum 24 inches downstream of turbocharger (if applicable)

- Avoid placing sensor at the extreme end of the exhaust

- Ensure no exhaust leaks upstream of the sensor

- Sensor must be powered whenever engine is running

Analogue Output Calibration

Typical Analogue Calibration Table

| Voltage (V)

| Lambda

| AFR (Gasoline)

|

| 0.00

| 0.65

| 9.7

|

| 1.00

| 0.78

| 11.5

|

| 2.00

| 0.92

| 13.5

|

| 3.00

| 1.05

| 15.4

|

| 4.00

| 1.20

| 17.6

|

| 5.00

| 1.36

| 20.0+

|

These values can be entered directly into the Race Technology software.

Troubleshooting

Common Issues and Solutions

| Issue

| Possible Cause

| Solution

|

| Unstable readings

| Poor grounding

| Check ground points

|

| Incorrect AFR

| Wrong calibration

| Re enter voltage table

|

| Sensor error

| Sensor contamination

| Inspect or replace sensor

|

| No serial data

| Wiring error

| Check TX/RX connections

|

| LED flashing rapidly

| Sensor fault

| Inspect wiring or replace sensor

|

Further Information

For detailed installation and configuration instructions, refer to the Innovate Motorsports LC 2 documentation.

For integration with Race Technology products, see the DL1, DASH, and ECU interface manuals.